Facility Management – Reducing man power required to perform inspections and prevention of accidents

It has come time to reexamine the way we manage equipment at large-scale facilities. This field has already been optimized to the maximum extent possible, thus relying on the same methods is not likely to yield further efficiency gains. Furthermore, due to labor shortages [in several advanced economies like Japan] makes it harder and harder to secure the man power necessary to confirm equipment status.

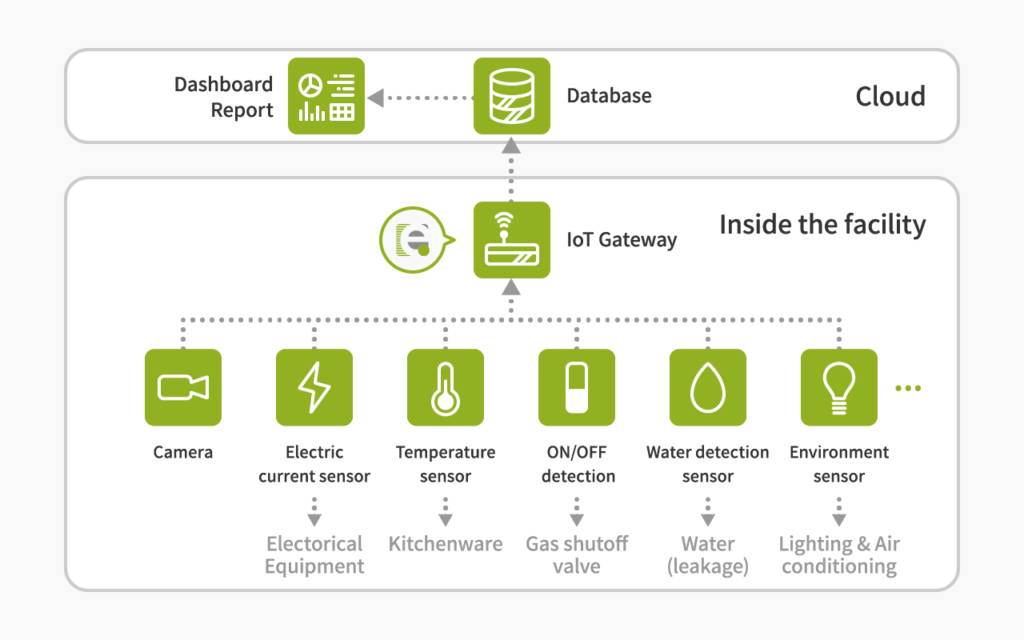

Traditional facility management is heavily dependent on people. Because the impact of a failure at large-scale facilities is so serious, the maintenance structure to manage those facilities has to be quite elaborate. For example, after closing, security guards need to go to kitchen areas to physically confirm that fire hazards such as heat sources and gas mains are completely shut off.

These tasks can be replaced by IoT. Gas leaks can be detected with sensors, values from devices like gauges and meters that need to be read can be obtained using image processing. Setting up a LoRaWAN network on site allows the data to be collected and transmitted wireless to the cloud, where a variety of visualization tools can be used to display the entire facility’s status remotely.

However, in this case, the data collecting devices would be located throughout the facility, so managing and operating them is very difficult. Using enebular makes operating them easy.