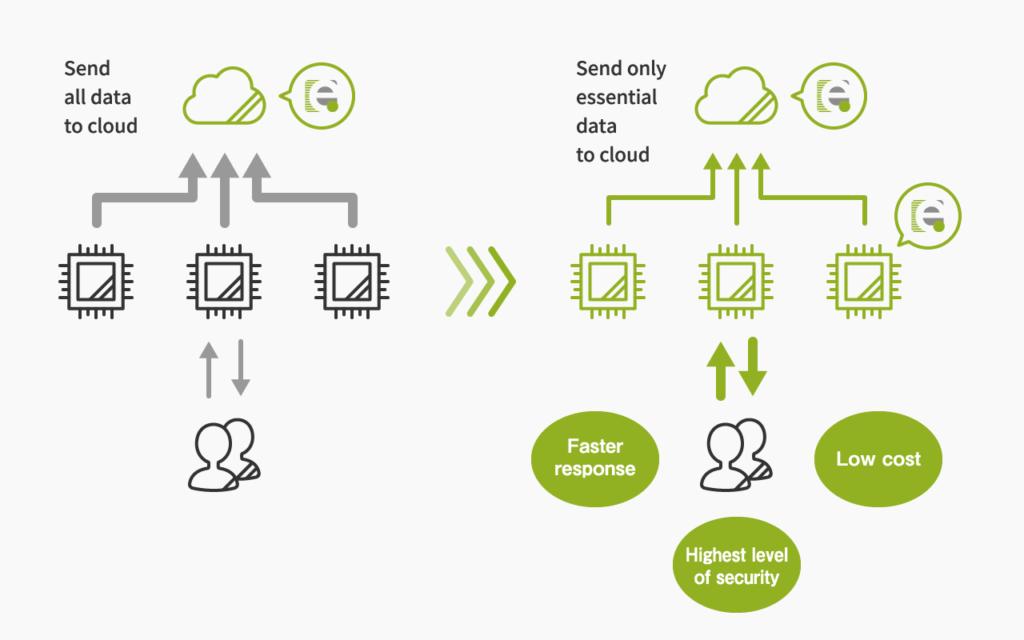

Combination of AI and IoT has tremendous potential for business. Enabling AI to function on the edge side makes it possible for only the essential data to be sent to the cloud, achieving quick response times and solid security at lower costs.

enebular supports development of distributed AI and IoT systems by running on both cloud and edge devices. enebular’s features also make the combination of AI and IoT work more effectively. For example, once an inference model is created, it may not be effective forever. When a better inference model is developed in the cloud, it is necessary to update the previous model running on edge devices. enebular allows the inference models deployed on hardware dispersed in different locations to be updated remotely. This feature is also effective for updating inference models which operate according to a pre-set time or condition.

Up till now, technicians had been adjusting the amount of chemicals to be used depending on the status of the production line. However, yields may drop due to a change in materials to comply with environmental regulations. By applying machine learning to the correlation between sensor data and production quantity and quality, a digitalized optimum product formula can be created for each product. Furthermore, the formulas can be updated remotely, based on sensor data and production plans, thusachieving modification to the production line in a short period of time, with the aim of improving yields.

Electronic PartsProduction Equipment Manufacturer

Reduced downtime by installing preventive maintenance functionality

By installing preventive maintenance functionality, new equipment can work continuously without break-down. Applying machine learning to the correlation between sensor data and equipment failure makes it possible to discover parameters that are more essential to predict failures than the ones previously considered effective. Furthermore, installing AI inference models on the next generation equipment enables requests for inspection and part replacement to be sent to the help desk automatically.

Construction Site

Progress monitoring and theft prevention by image analysis

General progress of construction work can be tracked by analyzing photo images taken at regular intervals and analyzing the changes. Detecting abnormal values from changes in the images and sending alert e-mails helps reduce the burden placed on foremen supervising multiple sites. In addition, by automatically switching the inference models after-hours, theft of construction machinery and materials can be monitored and prevented.

Shopping Mall

Signage advertisement matched with customers’ attributes

Real-time analysis of customer attributes based on security camera video can give insights to alter and display digital signage with customized purchase recommendations according to the season, time of day, special events, leading to increased sales per customer. Intelligent cameras determine the attributes locally at the edge and link them directly with signage, contributing to reduction of data transmission costs to cloud, and provides security for sensitive personal data.